INTRODUCTION

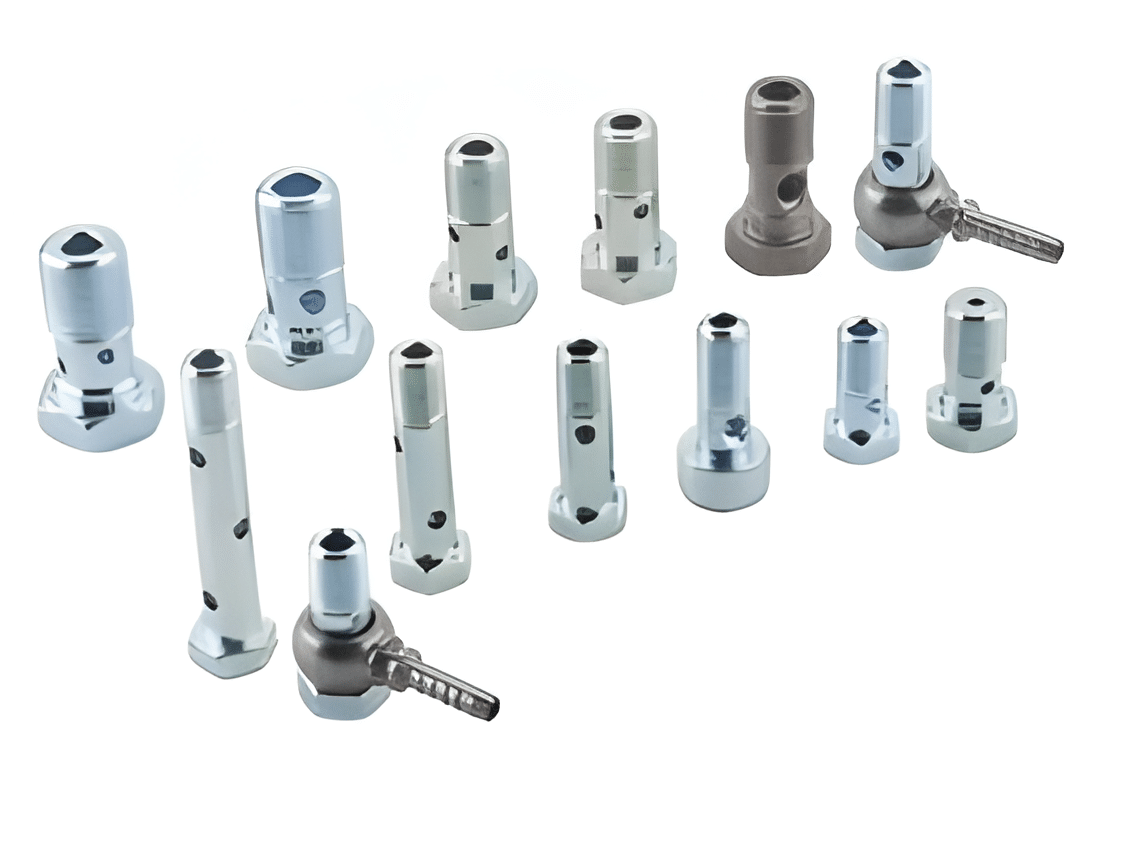

In industrial manufacturing and construction projects, the quality and fit of hardware directly affects equipment performance and productivity. However, facing a large number of hardware fittings on the market, how to choose the most suitable product? This guide will help you quickly master customized high-precision industrial hardware

1.Determine the application scenario of the hardware

Applicable to different industrial hardware fittings construction range, hinge mechanical equipment manufacturing, equivalent to the

2.Choose the right material

The material of the hardware determines its durability and performance. The following are several common

Stainless steel hardware: corrosion-resistant

Carbon steel hardware fittings:

Hardware hardware: lightweight and

Zinc-proof

- Focus on standards and accuracy

Neighboring industrial top can ensure the stable operation of the equipment and reduce the failure rate. It is recommended to choose products that comply with international standards such as ISO, DIN and ANSI to ensure quality and compatibility. In addition, the male range and surface treatment (e.g. clear, curved, sprayed) should also be emphasized in purchasing.

4.Durability and weight analysis

High-strength hardware with stable quality can reduce the maintenance cost and enhance the overall price.

Conclusion

Choosing the right hardware not only improves productivity, but also reduces equipment maintenance costs and ensures our long-term stable operation. If you are looking for customized hardware, industrial dock or building accessory hardware, please feel free to contact