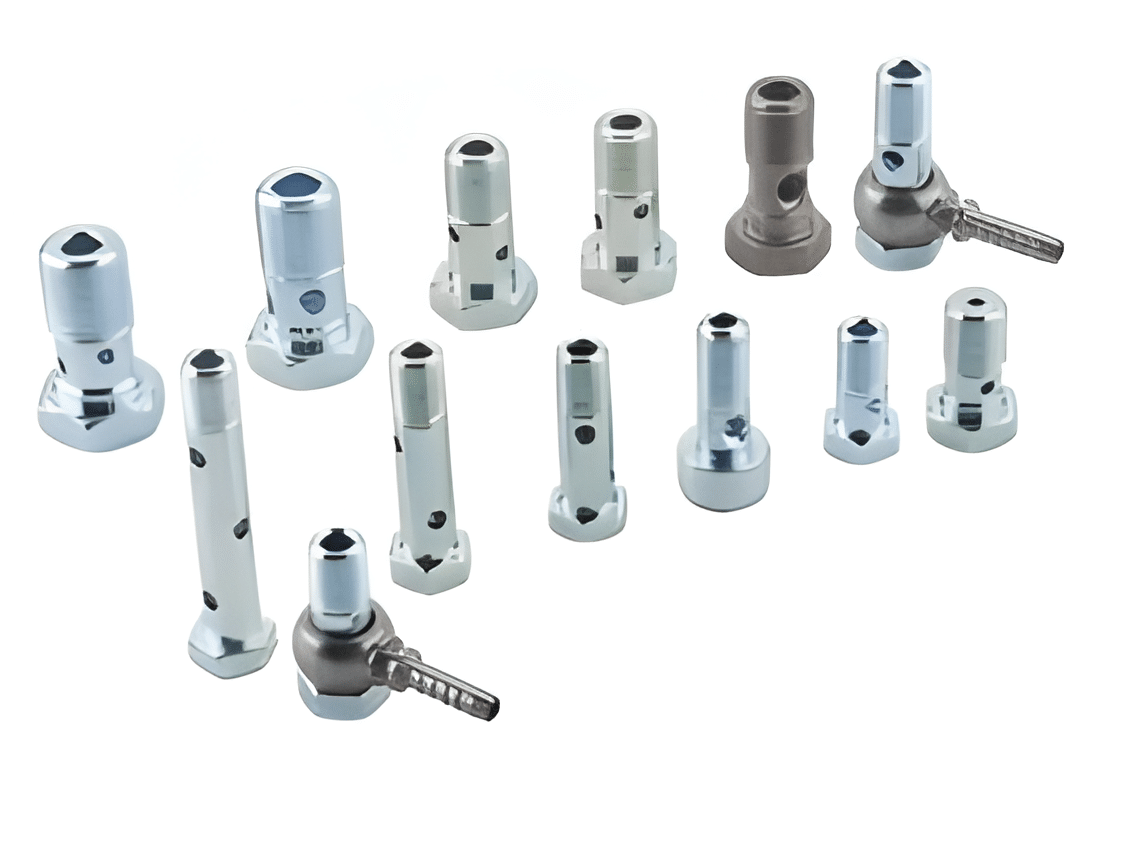

In the industrial manufacturing, construction and automotive parts industries, the quality of hardware accessories directly affects product performance and durability. Procurement staff often face problems with uneven quality, unstable supply and delivery delays. So how can you ensure that you are sourcing high quality hardware and minimizing risk?

- Identify key quality criteria

Different industries have different quality requirements for hardware fittings. Before procurement, the following standards need to be defined:

Material requirements: performance and application scenarios of materials such as stainless steel, aluminum alloy and brass.

Processing accuracy: especially for high-precision parts in the automotive and machinery industries.

Surface treatment: such as galvanization, electrophoresis and oxidation treatment, which affects corrosion resistance and service life.

Certification standards: International certifications such as ISO, CE and RoHS are important references for quality.

- Select reliable suppliers

Qualified hardware fittings suppliers should have the following characteristics:

Stable production capacity: Ensure long-term supply without interruption due to production problems.

Strict quality control: have perfect quality control process, such as raw material inspection and factory inspection.

Experienced: Suppliers who have worked with well-known brands are usually more reliable.

Good reputation: Reliability of suppliers is judged through customer evaluations and third-party reviews.

- Sample testing and small-volume purchasing

Before purchasing in large quantities, the following tests are recommended:

Dimensional testing: Use tools such as calipers to confirm that the product meets specifications.

Durability testing: such as tensile strength and hardness testing to ensure compliance with application requirements.

Surface Quality Inspection: Observe the uniformity of plating and the effect of anti-rust treatment.

Small batch trial: Observe sample performance in a real production environment.

- Optimize the procurement process to reduce risk

Signing detailed contracts: including product specifications, lead times and indemnification clauses

Audit suppliers regularly: evaluate them annually to ensure they meet company standards.

Maintain multiple supply channels: avoid supply disruptions due to single-supplier issues.

Utilize technology to track orders: Use ERP and MES systems to monitor order status in real time.

Conclusion

Choosing high-quality hardware not only improves product quality, but also reduces maintenance and after-sales costs. Through strict quality standards, reliable suppliers, scientific testing process and perfect procurement strategy, you can effectively reduce the procurement risk and ensure the stability of enterprise production.

If you are looking for high quality hardware accessories, welcome to contact us. We provide high-performance products that meet international standards to help your business grow!