In the automotive repair industry, efficiency and precision are essential. Many mechanics face issues like poor tool quality, long repair times, and operational errors. Choosing the right auto repair tools can boost efficiency, cut down on errors, and enhance customer satisfaction. This article will guide you through essential auto repair tools, shopping tips, and practical examples to help you find the best options.

- Industry Pain Points: Why Do Auto Mechanics Need Good Tools?

- Long repair times: Low-quality tools can complicate disassembly and assembly, slowing progress.

- Precision issues: Unsuitable tools may cause screw slippage and damage parts.

- Fragile tools: Poor tools break easily, raising costs due to frequent replacements.

- Lower customer satisfaction: Slow repairs and inconsistent quality hurt customer trust.

Research shows that using quality tools can improve efficiency by over 30%. This reduces rework and customer complaints linked to tool issues.

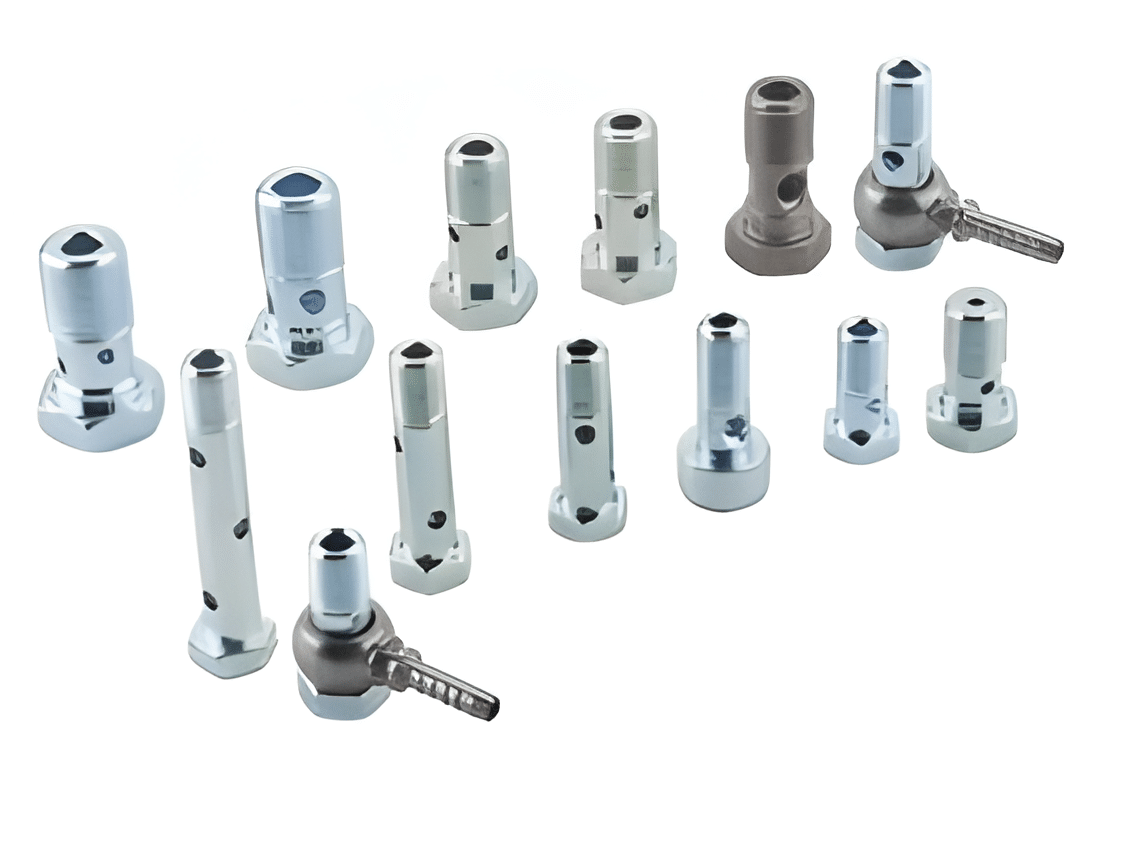

- Recommended Professional Auto Repair Tools & Product Comparison

- Hand Tools: Essential for precise maintenance

- Wrenches (ratchet, plum): Great for fine adjustments and torque control.

- Screwdrivers (magnetic, ratchet): Enhance disassembly and keep screws from falling.

- Pliers (sharp-nosed, diagonal-nosed): Ideal for gripping and cutting tasks.

- Pneumatic/Electric Tools: Speed up maintenance

- Impact Wrenches (pneumatic/electric): Quick bolt removal and installation boost efficiency.

- Electric Screwdriver: Reduces hand fatigue during long assembly tasks.

- Hydraulic Jack: Quickly lifts vehicles and ensures stable support.

- Durability and Cost Comparison: Different brands and materials vary in durability and price. High-quality alloy steel tools may cost more initially, but they last longer and save money in the long run.

- Real Case: Improving Maintenance Efficiency in a Repair Shop

- Case Study: An auto repair shop improved maintenance efficiency by 30% with high-quality tools.

- High-torque impact wrenches cut disassembly time.

- Magnetic screwdrivers reduced small part loss and improved accuracy.

- Long-life alloy steel wrenches decreased replacement frequency and saved costs.

Feedback from mechanics: “After upgrading our tools, maintenance efficiency soared and customer satisfaction improved.”

- Tool Use & Maintenance Guide (Enhance Longevity)

- Proper Use and Maintenance: Extend tool life with these tips.

- Regular Cleaning: Keep dust and oil from affecting performance.

- Proper Storage: Use toolboxes or hangers to prevent damage or loss.

- Lubrication: Regularly oil pneumatic tools for smooth operation.

- Avoiding Common Mistakes: Prevent tool damage.

- Avoid Overloading: Using a small wrench on a large bolt can break the tool.

- Correct Operation of Power Tools: Prevent overheating and battery drain.

- Conclusion & Call to Action

Choosing quality automotive tools boosts repair efficiency, reduces breakdowns, and increases customer satisfaction. If you need durable and effective auto repair tools, check out our selection today!